VVTi / VTC configuration

| Vehicle | Cams Controlled | Voltage | Frequency Range (Performance Setups) | Base Duty Cycle |

|---|---|---|---|---|

| Audi S4 (2010-2016) | Intake & Exhaust | 12V | 200-300Hz PWM | 0-100% variable (50% hold typical) |

| BMW 335i (2007-2013) | Intake & Exhaust | 12V | 200-300Hz PWM | 50% hold typical |

| Chevy LS (Gen IV, 2007-2015 VVT) | Single cam (pushrod) | 12V | 200-300Hz PWM | 50% hold typical |

| Ford Mustang (2011+ Coyote) | Intake & Exhaust (4 cams) | 12V | 200-300Hz PWM | Higher for retard (50% hold typical) |

| Honda Accord (2003-2007 2.4L VTEC) | Intake | 12V | 200-300Hz PWM | 50% hold typical |

| Honda Accord (2008-2012 3.5L VCM) | Intake (all cams) | 12V | 200-300Hz PWM | 50% hold typical |

| Honda Civic (2006+ iVTEC) | Intake (VVT) + both (lift) | 12V | 200-500Hz PWM | 50% hold typical |

| Honda Fit (2009-2013) | Intake | 12V | 200-500Hz PWM | 50% hold typical |

| Honda S2000 (2000-2009) | Both (lift only) | 12V | N/A (switched on/off) | 0/100% (on/off) |

| Lexus IS300/SC300 (1998-2005) | Intake | 12V | 250-300Hz PWM | 50% hold |

| Mazda Miata (NB2, 2001-2005) | Intake | 12V | 250-285Hz PWM | 30-45% (hold/move) |

| Mitsubishi Evo X (2008+) | Intake & Exhaust | 12V | 300-306Hz PWM | 50% hold typical |

| Nissan 240SX (S14 KA24DE, 1995-1998) | Intake | 12V | 250-300Hz PWM | 50% hold |

| Nissan 350Z/370Z (2003-2018) | Intake | 12V | 250-300Hz PWM | 50% hold |

| Nissan G35 (2003-2008 VQ35DE) | Intake | 12V | 250-300Hz PWM | 50% hold |

| Nissan GT-R (R35, 2009+ VR38DETT) | Intake & Exhaust | 12V | 250-300Hz PWM | 50% hold |

| Nissan Silvia/240SX (S13/S14/S15 SR20DET, 1989-2002) | Intake | 12V | 250-300Hz PWM | 50% hold (or 0/100%) |

| Nissan Skyline (R33/R34 RB25DET NEO, 1993-2002) | Intake | 12V | 250-300Hz PWM | 50% hold |

| Subaru WRX (2004+) | Intake (single) or both (dual AVCS) | 12V | 150-300Hz PWM | 50% hold typical |

| Toyota Celica (2000-2005 VVTi) | Intake | 12V | 250Hz PWM | ~50% hold |

| Toyota FR-S (2013-2016) | Intake & Exhaust | 12V | 150-300Hz PWM | 50% hold typical |

| Toyota MR2 (2000-2005) | Intake | 12V | 250Hz PWM | 37% at idle |

| Toyota Supra (1998-2002 JDM VVTi) | Intake | 12V | 250Hz PWM | ~50% hold |

| VW Golf (2018-2019) | Intake & Exhaust | 12V | 200-300Hz PWM | 50% hold typical |

Adjusting cam angle safely when road tuning

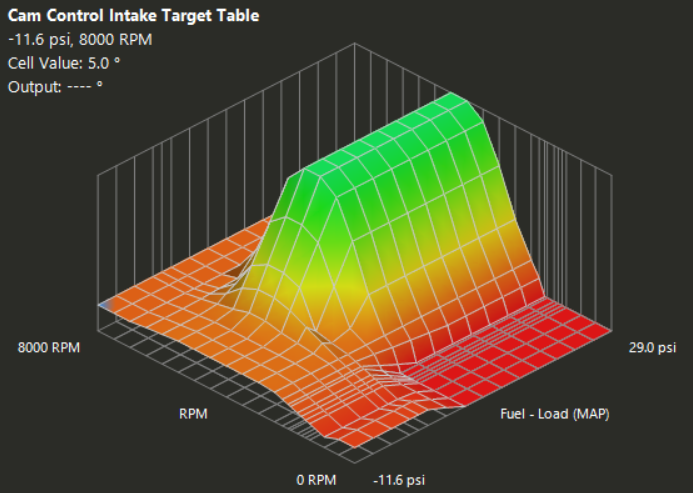

Target Angle Safety: The adjacent picture shows my cam angle chart, and this was built via a street tune. I need to rent dyno time and put my car on the dyno, but until then I'm running this. There's no real way to know what your ideal cam angle is unless you put a car on a dyno. I started with the basemap that Haltech provides, and I increased the fuel amount before I increased cam angle in small increments. The angles I chose are all just theoretical based on how much air flow I think the engine should have at that RPM. The increased fuel amount is so I don't make the engine run lean as the angle increases. Then as I drive the car, the "Long Term Fuel Trim" fine tunes the air-to-fuel ratio for me. Why does the engine go lean when cam angle is higher? The greater the cam angle, the more airflow into the engine at that RPM, so this changes air going into the engine, but the fuel amount is predetermined in the fuel table.

How is a dyno better? It allows you to monitor the power output from the car while you're holding RPM steady. To determine the best ideal cam angle you will increase fuel on your fuel map a little first at the RPM and boost you're car is holding steady at, then increase angle, and watch power level go up or down. If power output drops, then move your cam angle in the other direction. After every new angle, I like to make sure my AFR is on target, then make small adjustments to my timing map while still watching power output. Repeat this same process for the areas where the car is commonly driven.

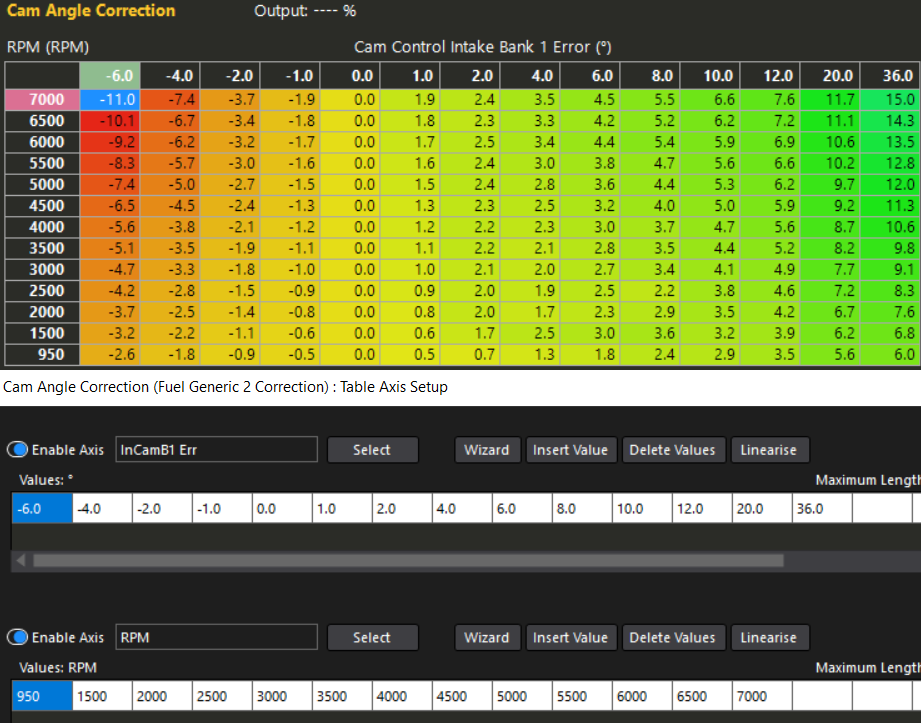

cam angle fuel correction table

Automatically adjust fueling with cam angle error: If you notice in the adjacent screenshot of my Haltech NSP tuning software, I've built out a custom table to add fuel if the cam angle increases beyond the target, or it decreases fuel if the cam angle is below the target. The cam naturally goes off target slightly during different driving conditions. This correction table is added when the "generic correction" box is checked, then you can name it what you want. Set the y-axis to RPM and the x-axis to "Cam Control Intake Bank 1 Error" and set the angles from -6 to 36 as I have.

Why? The P.I.D. values are difficult to dial in perfectly on a cam due to varying oil temperature and varying oil pressures at different RPMs. This can be a pain. Install an oil temperature sensor and change all of your cam P.I.D. tables to adjust based on oil temp instead of coolant temp. Read more about this below where I talk about oil temperature sensor benefits in variable valve controlled cars.

Protection Benefits: This helps keep your fuel on target in the unlikely event that your solenoid fails or if your plastic electrical connector slips off. Also, during normal driving conditions, as mentioned above, the P.I.D. values will cause the cam to move slightly off target. Most of the time this is only about 1 degree, but it keeps your engine running at a good AFR since the cam angle impacts AFR.

Downsides? The only real downside I've noticed this this is when the cam angle changes after a shift event, the engine has a tendency to run rich for about a half second. This is due to the cam angle changing so quickly near the top of the pistons, the ECU sends the command to alter fueling based on cam angle but the down-rev of the engine isn't demanding fuel, so it's rich for about a half second.

oil temp sensor needed to refine P.I.D.!

Why do i say this? I touched on this above, but going a little deeper. It gets even more difficult to dial in your camshaft perfectly if your P.I.D. tables are set to adjust based on coolant temperature (this is default in Haltech's basemaps since most people don't have an installed oil temperature sensor). Coolant heats up faster than oil does, so even if you dial in your P.I.D. values perfectly today, if the weather is cooler tomorrow it will take longer for your oil to come up to temperature. When this happens you will need to adjust your P.I.D.s for your cams again. If you do decide to install an oil temperature sensor, you can follow the information on the "temperature sensors" portion of this website regarding the wiring and configuration. This sensor allows you to log your oil temperatures while you're on the track so you can determine whether you need a thermostatic plate and oil cooler on your setup.

What sensor to buy? The adjacent picture is a 2 wire temperature sensor that you can purchase for relatively cheap here. This is a 1/8 NPT sensor that fits most aftermarket parts. Make sure your thread on your car takes 1/8 NPT, some cars take 1/8 BSPT and others are m10x1 thread like the PST-F1 found here.