Injector flow and fuel pump calculator

Single Injector Flow (CC): 0 cc/min

Single Injector Flow (lb/hr): 0 lb/hr

Fuel Pump Flow Required (lb/hr): 0 lb/hr

Fuel Pump Flow Required (LPH): 0 L/hr

Desired Horsepower: Enter your realistic HP goal.

Number of Cylinders: Enter your number of cylinders (or if you're running 2 injectors per cylinder then enter your total number of injectors).

Injector Duty Cycle: This is basically how hard you want the injectors to work relative to their max output, above about 90/95% of their max (duty cycle) the injectors life-span will be weakened. Generally people will plan for a 80% duty cycle for safety. You can still buy a larger injector, you just can't buy smaller than this and expect to reach your HP goal.

Fuel Type: E85 and gasoline have different weights, this affects the fuel flow through your system, the pump will need to work harder. For this reason, the calculator assumes an average weight of 6.17 lb/gal for gasoline and an average weight of 6.55 lb/gal for E85.

Induction Type: BSFC or Brake-Specific Fuel Consumption is relied on for this part of the calculation. hotrod.com has a nice article on this, but if you don't want to read it, simply put, it's how well your engine converts fuel to power. This calculator assumes BSFCs of 0.50 (N/A), 0.60 (Turbo), or 0.62 (SuperCharged) for gasoline engines. It assumes BSFCs of 0.70 (N/A), 0.85 (Turbo), or 0.87 (Supercharged) for E85.

Safety Margin checkbox: Checking this box factors in a 20% safety margin to this calculation, ensuring you are not pushing your fuel pump to the max.

Injector Size: This is the output of your injector size, you'll use this to look up the size injector you're going to purchase in pounds/hr or in CC/min

Fuel Pump Flow: This is what you'll use to purchase your fuel pump, most are rated in LPH (like the walbro 450 that flows close to 450 Liters per hour).

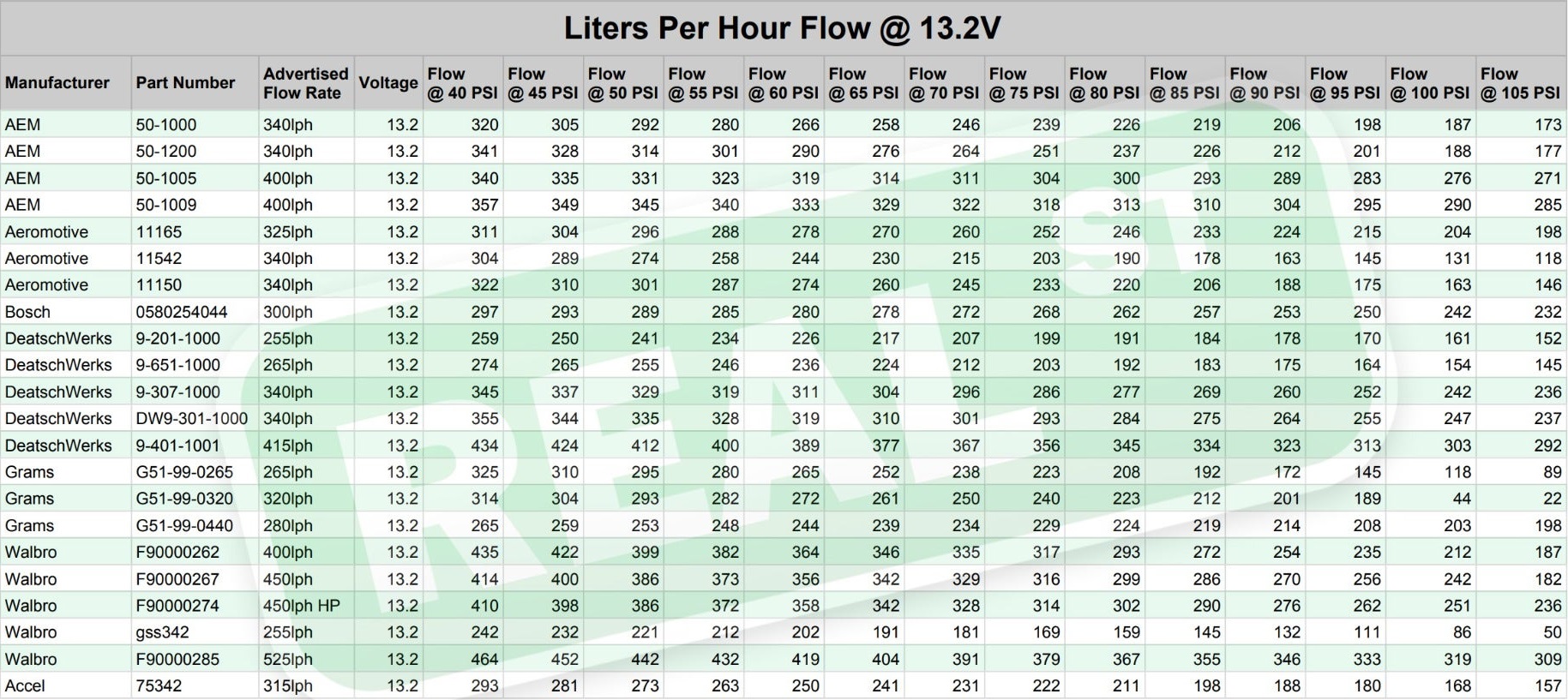

Important note: It's good to consider that as your boost pressure increases, the fuel pressure will need to overcome the boost pressure, and your fuel pump flow willl decrease below the factory rating. Basically, as boost rises, your fuel pump will flow less. This is partially due to your fuel pressure regulator regulating the fuel pressure in your fuel rail to overcome boost pressure.

before you buy your fuel pump!

Before you select your fuel pump, there are some things that you need to know. First of all, if it states that it flows "450LPH" on the box, when it's actually in your car it will flow a little less. Realstreetperformance.com did a test comparing the actual flow of different fuel pumps, and you can read about it here. The adjacent picture shows a screenshot from their webpage.

E85 flow vs petroleum: Your engine consumes more fuel when you run E85, so you'll need to factor this in to your build. You may need 2 fuel pumps.

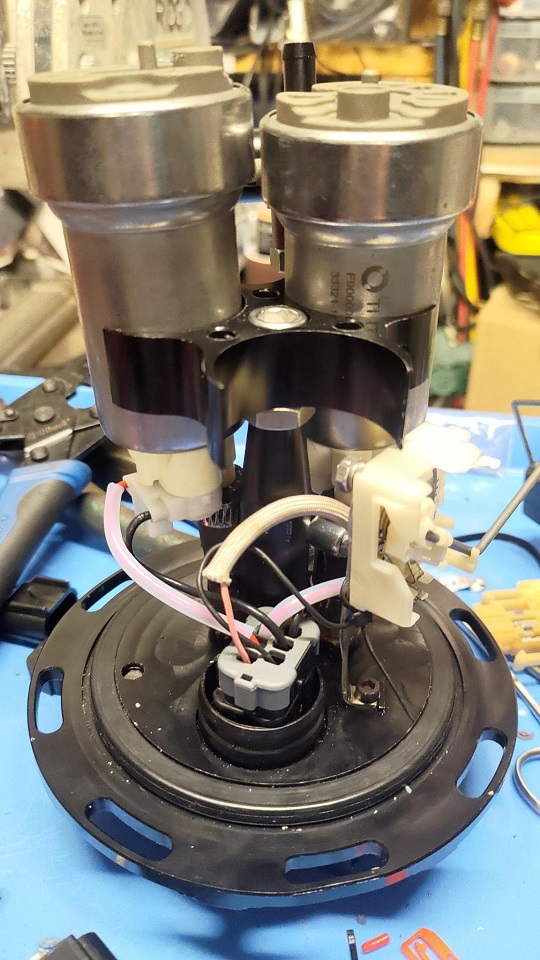

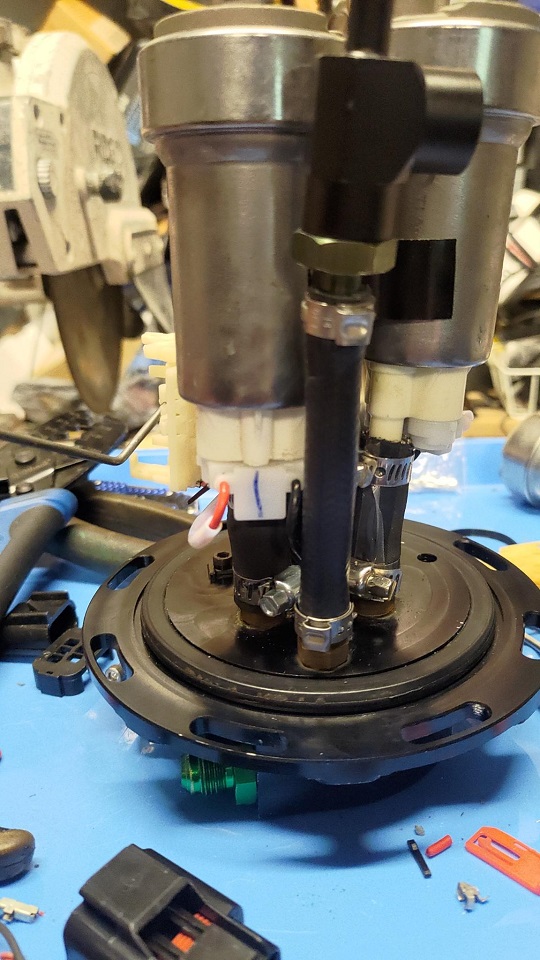

Dual fuel pump setup: This is not an overly complicated installation. The fuel pump kit I'm using is actually cheaply made so I'm not mentioning the brand since I don't want to trash-talk the manufacturers. The 9 inch corrugated tubes needed to be looped around once to connect the outlet of the pump to the bottom of the tophat (visible in the 3rd picture of the adjacent slideshow), the loop in the hose causes it to be pushed down or at an angle. I ended up abandoning the corrugated tubes since they were easy to nick while slipping into the tank(and a scratched hose isn't rated for the same PSI anymore). I used E85 rated rubber hose rated for almost 300PSI and slipped this straight on to the top of the pump while turning the pumps to align with the port on the top hat (visible in the pictures also).

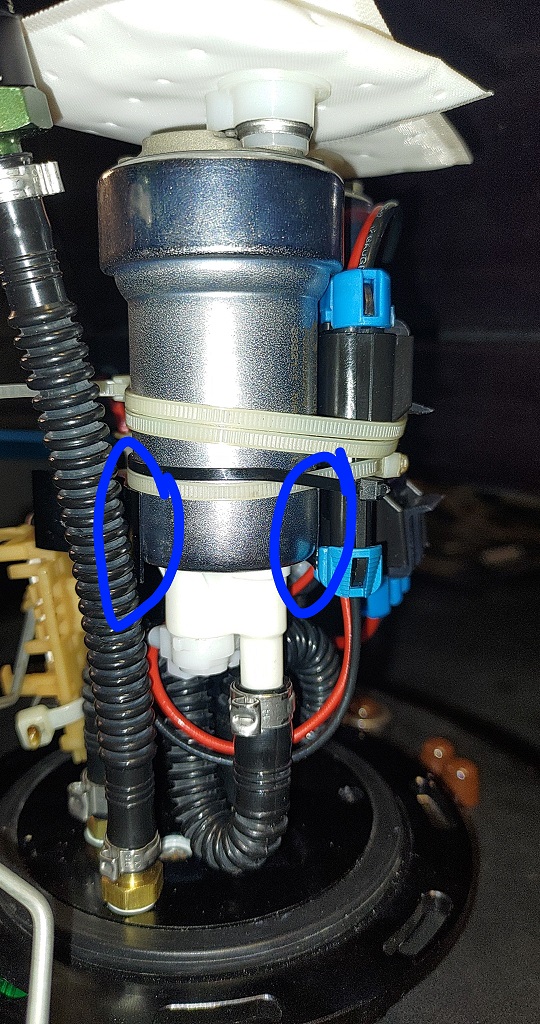

Modifying the fuel pump hanger: 1) I needed to "extend" the support arm lower with a stainless nut at the base of the fuel pump holders (the assembly is upside down in the pictures but it's visible in the 1st picture) since the holders held the pumps near the top after the hose was installed leading to them wanting to fall easily. The 3rd picture has the blue circles that highlight how loose the holder holds the pumps.

2) The connector insulators that came with the kit that were designed to be in fuel disintegrated. I removed the insulator block from the connector completely, I later learned that gasoline is more of an insulator than a conductor, so having wires in the connector that are exposed to fuel will not create a connection, I called racetronix and a couple other manufacturers and distributors of the in-tank Apex connector, and they told me to not use the seal block.

3) The pumps fit much better with the straight hose, and they don't drop too low to push on the bottom of the tank but they are low enough to grab fuel on a low tank.

4) The side effect of the straight hoses was I needed to turn the fuel level sender slightly toward the front of the car from the original orientation, so I needed to bend the float arm back toward the center of the car since it was rubbing the front of the tank after being turned.

Trigger the second fuel pump at __ boost: You don't want both pumps running at all times, it's easy to stage them in most tuning platforms, so the secondary pump turns on at a higher boost level via a second relay and second relay output trigger. Me personally, I would enable a Check-Engine-Light to trigger in Haltech's software if your fuel pressure drops too low. Then monitor fuel pressure while on a dyno (or hard acceleration), if fuel pressure begins to trigger your engine protection CEL, enable the second fuel pump about 5psi of boost below this point.

Removable intake manifold assembly (intact)

The intake manifold I bought used off of a Supra locally on Craigslist, it had seen approximately 20 years of use. After a sandblasting and a powder coat it looked new again. The Radium parts (fuel rail, injector pulse damper, fuel pressure regulator and pressure gauge) add a touch of elegance. The Boash 82mm throttle body on the front of the Greddy intake manifold curves around the OEM IS300 power steering reservoir perfectly!