First things first

If you're wiring in something like a radio or car alarm, butt connectors will be ok, but if you're building your first engine wire harness you'll need to pay close attention to how tight your wires are, and how neat they are routed around objects. And if you're splicing into a wire NEVER EVER use vampire taps (aka quick lock splices).

Are the wires near something sharp? Could they bounce and rub something? Even if you secure them with a zip tie, that could be better than nothing.

Are they near something hot? DEI makes some a heat shield/sheath that I've used to protect wires around turbo or exhaust pipes.

Get a set of barrel crimpers with barrels and some heatshrink, it's faster and safer than soldering. A lot of guys frown on soldering saying it makes brittle connections (which it does), but if your solder joints are heat-shrunk sealed and aren't in an area where they'll bend it'll be perfectly fine. I've soldered engine harnesses that lasted 10+ years. The big downside is inhaling the tin/solder fumes and the health risks associated with breating in those fumes over a long period of time.

AMAZON AD SPACE

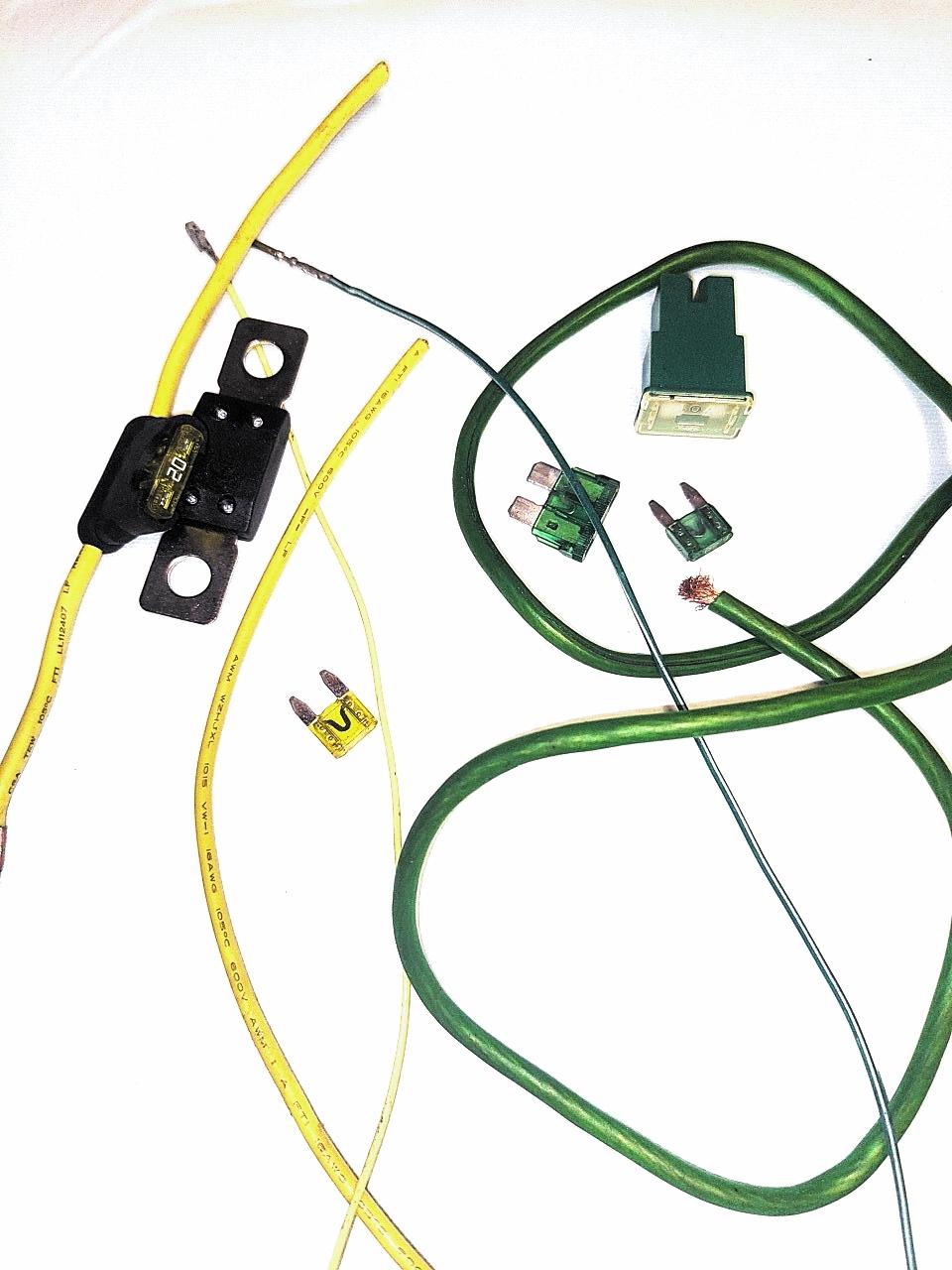

Wire gauge, amp rating, and why that's important!

The easiest way that I've come to understand this, is that electrical devices don't think about the energy they are able to use, they just pull once they're connected. This "pulling" can be damaging if the wire is too small, the wire can't handle the demand that's being placed on it, but it tries anyway. This creates heat, and potentially melts wires too small for a device. This is why most vacuum cleaner wires get warm. Heat is what blows a fuse, the fuse should be the weakest link in your wire setup. Simply put, an "amp rating" is what the wire can handle safely and the term "amp draw" is what a device will try to "pull" when it's connected to the voltage it requires. Devices have amp ratings that show its amp draw. Look up amperage charts for the voltage you'll be using, and wire your project appropriately!

- Not all wires are copper, some are CCA (Copper Clad Aluminum), and some are just aluminum. OFC (Oxygen Free Copper) is best. CCA and Aluminum need to be a larger gauge for the same amp rating.

- Small wires (20-22AWG) are great for triggering relays and some small sensors.

- Medium wires (18-20AWG) are great for sensors, small solenoids, boost valves, etc.

- Larger wires (12-16AWG) are great for fuel pumps, ignition coils, cooling fans, etc.

- Heavier wires (8-10AWG) are generally used for power feed.

- Total amp draw should be calculated for each device behind a fuse, and I usually add around 25%. So I'll wire a fuel pump that draws 30a on at least a 40a fuse.

- Trigger sensors and speed sensors generally should be shielded.

- If you're wiring fuel pumps in a gas tank, use PTFE-coated wire since it resists gasoline better.

Relays! Relays are absolutely amazing, there are quite a few cool things you can do with them, and I have that stuff on my relay page here.

The primary use is to use is to place it near your device that needs large wires (fuel pump, fog lights, fan, etc), and run 1 small gauge wire to trigger the relay on. Save money and space with small wiring running to your button in your interior. On a Haltech, connect a relay (pin 85) to an open DPO wire, then connect Pin 86 to ignition switched power. Pin 30 is fused power source, and pin 87 is the fuel pump, fog lights, fan, etc. 5 pin relays can be used in place of 4 pin relays with no change to wiring.

There are other cool wiring methods to do some creative things with them that I discuss here.