Manifold Absolute Pressure sensors

| Vehicle | OEM MAP | Approx. Max Bar |

|---|---|---|

| Audi S4 02-23 | 3 Bar | ~1.6 Bar |

| BMW 335i 07-15 | 3 Bar | ~1.4 Bar |

| Camaro Supercharged 16-23 | 3 Bar | ~1.6 Bar |

| Challenger Supercharged 15-23 | 3 Bar | ~1.8 Bar |

| Evo (all) | 3 Bar | ~1.8 Bar |

| MKIV Supra | 3 Bar | ~1.6 Bar |

| WRX 02-21 | 3 Bar | ~1.5 Bar |

About: This section covers Manifold Absolute Pressure sensors. Not all vehicles are equipped with these, only a few turbocharged/supercharged models. You can add these sensors to an aftermarket ECU known as "Engine Management"

5v: This connects to the 5v power supply from the ECU the sensor is wired to.

Sensor ground: This needs to be shared sensor ground, not chassis ground.

Signal wire: This connects directly to the ECU

Troubleshooting: If the sensor is showing 0v, check your signal wire or 5v connection. If it is showing 5v, check your sensor ground connection.

Oil pressure Sensors

About: Most vehicles from the factory will have oil pressure switches that will trigger a low oil pressure warning on your dash below approx 7-10PSI (~0.5-0.7 Bar). This section covers oil pressure sensors on vehicles as they were from the factory.

Wiring

: The same wiring mentioned in the MAP section above apply to this sensor (5v, Sensor ground, Signal wire).

Troubleshooting: The same troubleshooting steps mentioned in the MAP section above can be followed.

| Vehicle | Voltage Range | Pressure Range |

|---|---|---|

| Audi S4 09-16 | 0.5v-4.5v | 0-145 PSI |

| BMW 335i 07-15 | 0.5v-4.5v | 0-145 PSI |

| Camaro 16-23 | 0.5v-4.5v | 0-145 PSI |

| Challenger 08-23 | 0.5v-4.5v | 0-145 PSI |

| VW Golf 15-21 | 0.5v-4.5v | 0-145 PSI |

Power Steering Press. Sensors

| Vehicle | Voltage Range | Pressure Range |

|---|---|---|

| Infinity G35 (03-08) | 0.5v-4.5v | 0-130 PSI |

| Lexus GS300 | 0.5v-4.5v | unknown PSI |

| Lexus IS300 | 0.5v-4.5v | unknown PSI |

| Nissan 350Z(03-08) | 0.5v-4.5v | 0-130 PSI |

| Nissan 370Z(09-20) | 0.5v-4.5v | 0-130 PSI |

About: Most vehicles from the factory will have P/S pressure switches that will help to raise idle slightly when the wheels are turned. This section covers P/S pressure sensors on vehicles as they were from the factory. Older vehicles used a vacuum switch that would raise the idle when the wheel was turned by opening a port that connected a vacuum line in and out of the power steering switch. Newer vehicles detect power steering pressure via a sensor or switch and send that data to the ECU for the idle to be raised.

Wiring: The same wiring mentioned in the MAP section above apply to this sensor (5v, Sensor ground, Signal wire).

Troubleshooting: The same troubleshooting steps mentioned in the MAP section above can be followed.

Adding a fuel or oil pressure sensor

Requirements: The main requirement for this is a standalone pressure gauge OR a full replacement programmable engine computer known as "engine management".

Wiring: There are 5 wires (5v, sensor ground, and signal) and all of the data needed for wiring and configuration can be found in the datasheet that will come with your sensor. It's important that your sensor ground is connected to the same device receiving the signal from the sensor. If you're using a standalone gauge, connect the sensor ground to that gauges sensor ground. If you're connecting this to engine management, connect the

Wire gauges: This be 18 or 20 AWG depending on the amp draw so consult your datasheet or mimic the OEM wire gauge for pressure sensors. Shielding is not necessary.

Which sensor do I buy? The sensor in the adjacent picture is a Haltech HT-010904 (150PSI) fluid pressure sensor, but research your expected oil pressure, fuel pressure, (or even power steering or transmission line pressure) and buy a sensor that covers your range.

Configuration: The configuration is mentioned below regarding all of these pressure sensors.

Configuration

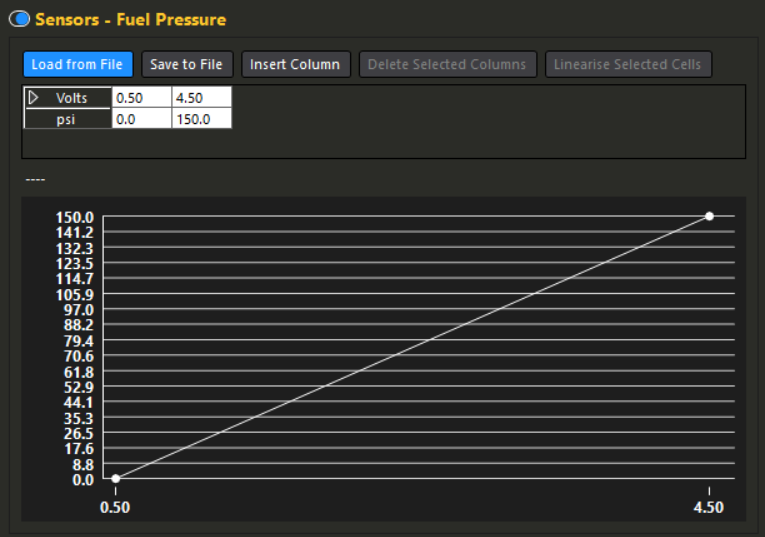

Overview: The adjacent picture shows a fuel pressure sensor configuration (software is Haltech NSP), but the same configuration steps can be followed for MAP, P/S, Coolant Pressure, Oil Pressure, Transmission Line Pressure, etc.

Volts: Input data into the white boxes beside the "Volts" text. Generally the values in here will be 0.5 to 4.5, but consult your datasheet that came with your sensor.

PSI: I have entered my data in PSI, if you're using Haltech then you can change the measured units under 'preferences>units' at the top banner. If your datasheet shows PSI, Bar, KPA, etc, then switch your unit preferences to reflect the units on your datasheet. Once you've done this, input the data. After this you can switch back to other units and the Haltech software will automatically convert the values.

Pull-up resistor: A pullup resistor should not be needed to be wired in (or enabled in the software), but consult your datasheet to verify.

Why add fuel, Coolant or oil pressure sensors?

Important Info on gauges: The AEM x-series gauge in the adjacent picture should not be relied on if you're expecting to save your engine from catastrophic damage. The gauge DOES have a data output, but the processing of the information before it relays it to your engine management can potentially be too slow if the fuel pressure drops, resulting in a lean condition before your ECU takes action. Other gauges are similar in terms of processing data and relaying it to an ECU. If you can, wire it directly to your aftermarket ECU.

Coolant Pressure Sensor: This is a little known sensor that can be added to your engine to notify you if your headgasket is leaking under high boost. I've found it to be slightly scary under normal driving, since the coolant pressure has a tendency to drop when the thermostat opens. In my Haltech diagnostics for this sensor I have a CEL set to trigger if it rises over my normal PSI.

Fuel Pressure Sensor: This can be used as a safety measure in the event that you're accelerating under full boost and a fuel pump fails. The ECU senses a drop in pressure and can limit throttle immediately to avoid leaning out.

Oil pressure sensor: For the same reasons mentioned above, this sensor can add a little more safety to your engine by detecting if your oil pressure ever drops.

Other pressure sensor uses: Crankcase pressure to monitor excessive pressure under high boost. Transmission line pressure. Barometric pressure (useful if you drive the car in massive elevation differences)