"Pickup" sensors

| Vehicle | Crank teeth | Crank sensor | Crank edge | Cam teeth | Cam sensor | Cam edge |

|---|---|---|---|---|---|---|

| 1ZZ/2ZZ | 36-2 | Hall Effect | Falling | 3 | Hall Effect | Falling |

| 2JZ VVTi | 36-2 | VRT | Rising | 3 | VRT | Rising |

| 350Z/370Z | 36-2 | Hall Effect | Falling | 3 | Hall Effect | Falling |

| Civic 88-00 | 12 | Hall Effect | Falling | 1 | Hall Effect | Falling |

| Civic 02-15 | 12+1 | Hall Effect | Falling | 4+1 | Hall Effect | Falling |

| Evo 7-9 | 2 | Hall Effect | Falling | 2 | Hall Effect | Falling |

| Evo 10 | 36-2 | VRT | Rising | 3 | Hall Effect | Falling |

| Miata 90-05 | 4 | Hall Effect | Falling | 1 | Hall Effect | Falling |

| Miata 06-15 | 36-2 | VRT | Rising | 3 | Hall Effect | Falling |

| Subaru EJ20/25 | 36-2 | VRT | Rising | 3 | Hall Effect | Falling |

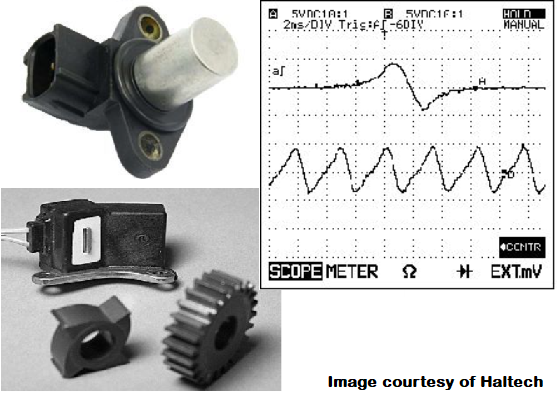

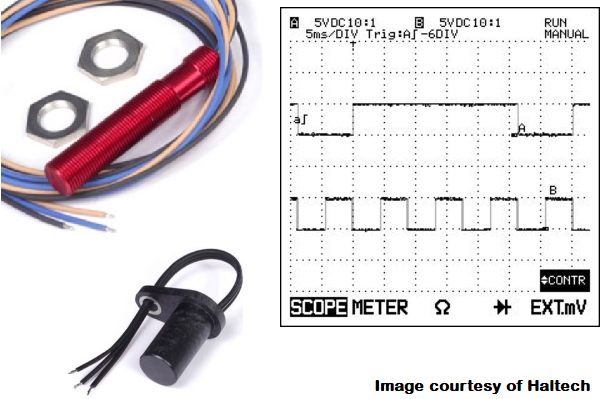

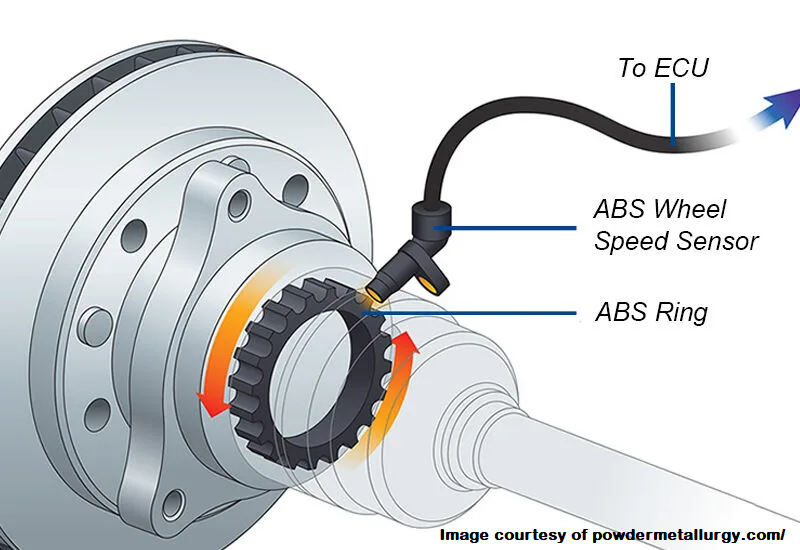

There are two main types of pickup sensors: VRT (Variable Reluctance Transducer) and Hall Effect sensors and they are both shaped similarly. Both sensors will be positioned within a few millimeters from a toothed wheel known as a "tone ring", "reluctor wheel", or simply called a gear or pickup wheel. The ring is a metal toothed wheel that provides position or movement data that is read by the Hall Effect or Reluctor.

The VRT sensor is an electromagnet (copper wrapped around iron) that sits near a gear tooth. When it passes near the gear tooth it produces a voltage spike. The ECU interprets these spikes as engine speed/position, wheel speed or gear speed. The hall effect sensor contains a transistor and electromagnet inside, and when metal passes near it the field is interrupted and the circuit opens. This produces an on-off signal. When each sensor is used on an engine, position data is important, the toothed wheel will have one or two teeth missing so the ECU can determine engine position for timing. On a transmission or driveshaft where speed is the thing being measured, there should not be a tooth missing.

Applications: Wheel Speed (ABS and Traction Control), Transmission Gear speed, Engine speed, Turbo Speed, etc.

TWO WIRE Reluctor (VRT) sensors

Wiring: VRT sensors are generally 2 wire. Polarity matters, but it will sometimes still operate with the wires reversed, just not perfectly. The sensor wire should be shielded and the shielding grounded at one end only, join the shield to the other sensor grounds. 18 to 20 AWG 2 conductor shielded wire works well. Toyota has been known to join the ground wires for cam and crank pickups together, separate these in custom engine applications, but refer to your aftermarket ECU's wiring diagram for specific information.

Configuration: These can be set up usually with "falling edge" and no pullup enabled. Consult your datasheet and ECU wire diagram for vehicle specific wiring. You may see "arming voltage" or something similar in your settings. The ECU will not use the signal from the sensor until it rises above the arming voltage, this is useful if you have interference at low sensor speeds.

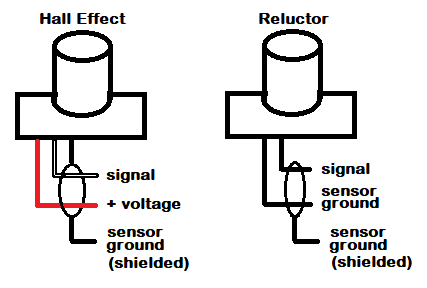

HALL EFFECT sensors

Wiring: Hall Effect sensors can be 2 or 3 wire, but are mostly 3 wires. Polarity matters. Sensor signal and voltage wires should be shielded and the shielding connected to the sensor ground on your ECU. The sensor ground for this sensor can be connected via the shielding of your shielded wire. Wire gauges can be 18 or 20 AWG depending on the amp draw so consult your datasheet or mimic the OEM wire gauge.

Identifying: This sensor has a similar shape to the VRT, and can be mistaken for it. 2 wire hall effect sensors are easily mistaken for VRT style pickups.

Configuration: These can be set up usually with "falling edge" and pullup enabled. Consult your datasheet and ECU wire diagram for vehicle specific wiring. You may see "arming voltage" or something similar in your settings. The ECU will not use the signal from the sensor until it rises above the arming voltage, this is useful if you have interference at low sensor speeds.

Testing and troubleshooting

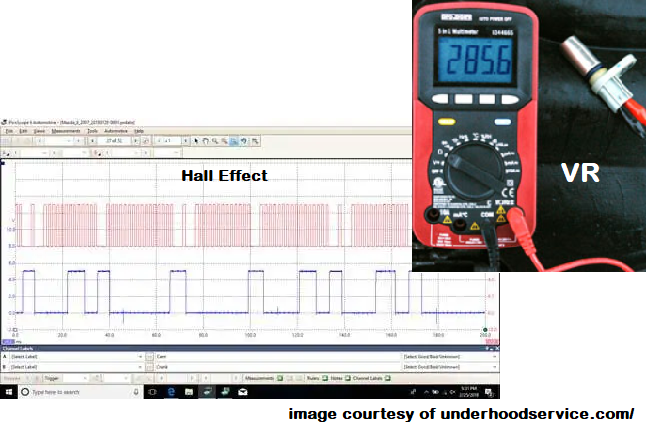

Oscillioscope (if you have access to one) or an OBD2 scantool with either a voltage readout or graphical interface to interpret sensor data for a Hall Effect.

Physical inspection. If you don't have access to an o-scope, verify your wiring first by disconnecting the sensor and the apropriate plug on your ECU, then test continuity with a multimeter (only for VRT). Once you've determined that you have continuity, reconnect your sensor and check for a signal again via your OBD2 scanner or o-scope.

OBD2 scantool: Connect your scantool to the diagnostic port, and find the data screens (or sensor data) portion of your scantool. Rotate your wheel with the car off the ground (or turn the engine over) while simultaneously looking at your scantool for voltage readings.

Multimeter: This can only be done on the VRT sensor, put each probe end on the sensor on the low resistance setting. Spin the wheel or engine, and watch for resistance changes. Compared the readings to your car's repair manual. You can perform continuity tests on a Hall Effect sensor, and you can measure voltage on the positive wire from the ECU, but there is no resistance check that can be performed.

Wiring

Hall Effect sensors generally have 3 wires: Voltage feed, sensor ground, and a signal wire. The sensor ground can be used as the shield if you purchased a 2 conductor shielded wire.

Variable Reluctance Transducer sensors will have 2 wires. They don't receive a voltage like the hall effect does. They generate a voltage spike when metal passes in front of the pickup which registers on the ECU. Technically both wires are "signal" wires, but polarity can matter.

Extra Information

VRT wheel speed sensors sometimes have shielding around the tone-ring/reluctor-ring, if this shielding is damaged it can provide erratic results to the ECU.

Hall Effect sensors are slightly more complex than VRT sensors, for this reason they are generally not as reliable, though they can produce a cleaner on-off style signal than the VRT sensor.

In a 2-wire hall effect sensor, there is a voltage wire and a ground wire. The ground wire is also the signal wire. (I should say again that this is not a common sensor, most hall effect sensors are 3 wire).